THE RESTORATION AND TRANSFORMATION OF A HOT ROD

"BERNADINE" - A 1929 FORD MODEL- A COUPE TURNED ROADSTER

THERE IS A LINK TO THE " WAYNEDALER" ARTICLE ABOUT BERNADINE FROM MAY 15, 1958 HERE

THERE IS A LINK TO A STORY ABOUT THE CAR IN THE FORT WAYNE JOURNAL GAZETTE HERE

AND AN ARTICLE ABOUT BERNADINE FROM THE FORT WAYNE NEWS SENTINAL HERE

THERE IS A GREAT ARTICLE ABOUT THE RICH AUTOMOTIVE HERITAGE OF INDIANA POSTED HERE.

It has been gratifying to receive all the comments and suggestions from those of you interested in the restoration and rebuild of the 1929 Ford Model A Hot Rod "Bernadine". Our founder Rick Kennell inherited the car with the passing of his father, Chuck Kennell in April of 2007. This is a photo diary of the restoration, we hope you enjoy it.

"BERNADINE" FROM 1958:

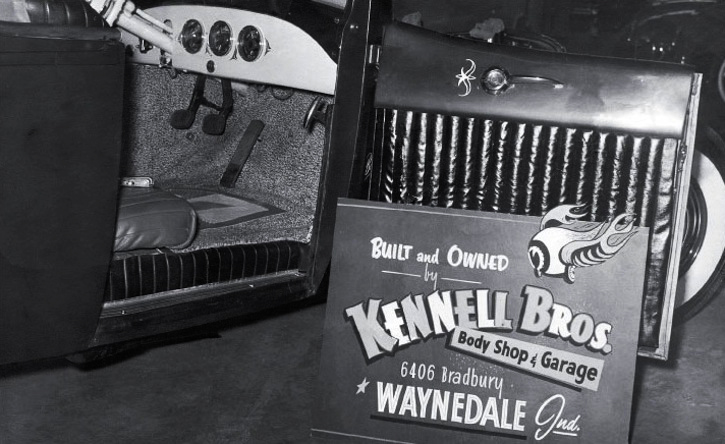

The three photos above are from from 1958, showing Chuck Kennell's original Hot Rod, "Bernadine", a 1929 Ford Model A roadster, with a 1936 Pontiac frame and a variety of odd parts from nearly every make and model of car you can imagine. That is Chuck's brother Bud Kennell in the driver's seat, in the top photo - as Chuck was taking the photo. These two brothers owned Kennell Brothers Body Shop and Garage for a number of years in the 1950's in Waynedale, Indiana. The ifn's founder and director, Rick Kennell, Chuck's only son, is partially in the picture. That is his arm just to the right of Uncle Bud's head! The other two photos were taken at the Allen County Memorial Coliseum, at the first ever "Hot Rod Show" in Fort Wayne in 1958.

MEET THE KENNELL BROTHERS

it's Bud on the Left and Chuck on the Right |

Bud was a first class body and paint man while Chuck specialized more on the mechanical side and also built racing motors. They worked together on the building of this car. They also owned and maintained a couple of stock cars ('36 and '39 Pontiacs) which they raced at the Fort Wayne Speedway and the South Anthony Speedway in the mid-fifties - in Fort Wayne. One of the stock cars is pictured below. The car pictured above was originally a coupe which Chuck and Bud cut the top off of. In this photo of "Bernadine", we believe that the motor was the original racing motor from the 1936 Pontiac. After Chuck and Bud displayed the car at the Fort Wayne Memorial Coliseum in 1958, Chuck was offered what was a nice sum of money at the time for the engine. Chuck wanted to put a big bore Pontiac engine in the car, so he sold it. Shortly after, Chuck started assembling a new motor from scratch, from a 1958 Pontiac 370 CI block he had gotten from a school in Detroit. Chuck's extensive knowledge of motors and even racing motors was very advanced for the time. It took Chuck a couple of years to assemble the motor, using nothing but hand-picked racing parts. Unfortunately, Chuck passed away before he could finish the entire re-build of the car, although he did spend a lot of time planning and gathering parts for it over the years. In honor of Bud and Chuck, Chuck's son, Rick has decided to take the car back to his own interpretation of approximately this 1958 version of the car - only upgrading the 1936 Pontiac chassis to a 1929 Model A Ford chassis, and utilizing the motor which was Chuck's pride and joy.

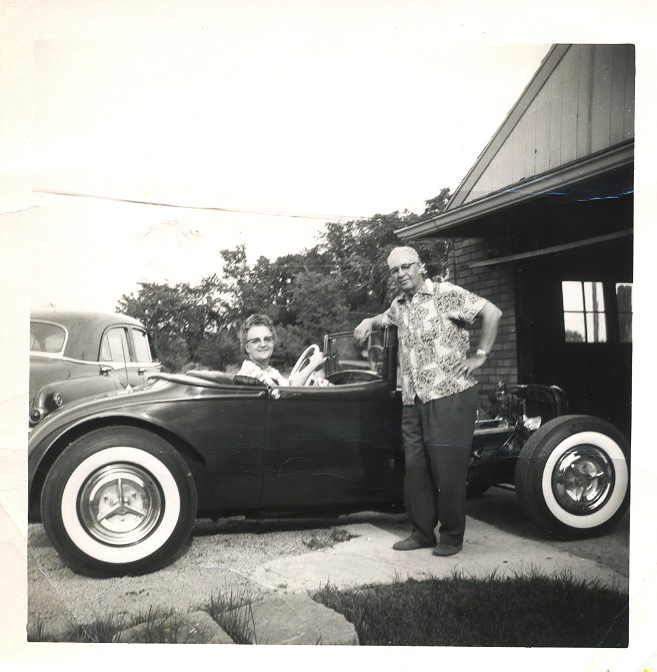

Here is another shot of the car with Grandma Ethyl Miller at the wheel and Grandpa Oliver Miller, standing. Note the too cool 1956 Oldsmobile "planet" tri-spinner hub caps. This photo was taken before the motorcycle fenders were mounted above the front wheels, but the car had already been pinstriped.

THE ORIGINAL RACE CAR:

.

"Bernadine" evolved from a lot of different parts, but none more important than this 1936 Pontiac stock car raced at the South Anthony Speedway in the mid-fifties by Bud and Chuck Kennell. The car was nicknamed "the tiny 6" for the small engine Chuck rebuilt and souped up. If you look carefully in the picture on the lower left you can see "the tiny 6" painted on the car above the rear wheel. We stumbled on these photos of the car, which was originally number 55. However, when they arrived at the track another car had number 55 so they painted a 1 in front of it. We believe that the third photo is also the final kiss of the wall which ultimately convinced Bud and Chuck to build "Bernadine" rather than sustain the heartache and expense of dealing with the constant repairs and fix-ups required to own a race car. Chuck and Bud are in the first photo, and that's Uncle Bill Miller, Bud and Chuck in the last photo.

Above is a shot of Chuck, Rick and Bud Kennell from 2002

TO ILLUSTRATE THE SUBTLETIES WHICH MAKE BERNADINE SO SPECIAL

There are many subtleties involved with "Bernadine". Bud and Chuck combined design features from a number of cars. The original frame and motor for Bernadine was a 1936 Pontiiac like this one:

The external door push buttons were taken from a 1947 Lincoln like this one:

The internal door handles and garnish molding were from a 1947 Kaiser Frazer

The taillights were taken from a 1950 Pontiac like this:

The grill shell came from a 1932 Model B like this:

The front bumper was based on a Circle K Sprint Car bumper from the 1950's:

The engine block was out of a 1958 Pontiac Bonneville like this:

But with cylinder heads on the motor from a 1955 Pontiac like this:

The hubcaps were one-offs from a 1956 Oldsmobile 98:

The front fenders and the rear license plate lights were both robbed from some type of vintage motorcycle:

"BERNADINE" AS WE FOUND HER:

The photos above were taken of "Bernadine" in April 2007 as we pulled the car out of Chuck's garage and loaded it on the flatbed. Since the car was already in Fort Wayne, Indiana, Rick chose ARTISANS ROD & CLASSICS, INC. out of Huntertown, Indiana to do the restoration work. Due to the incredible amount of parts Chuck had accumulated, it would have cost a couple of grand to ship everything out to New York before anyone even picked up a wrench. The crew at Artisan are pros, and auto restoration is their entire focus. Thanks to my cousin Kerry Kennell, Bud's son, I have also found an incredible interior man: Marcus Marquart of Marquart's Custom Creations in Fort Wayne. Marcus will be refurbishing the interior and fabricating the convertible top. Kerry happens to be a friend of Marcus or I probably wouldn't have been able to get in. Marcus is busy and sometimes booked up for over a year, even without a website; it's all word of mouth. He does everything from custom rods to classic cars to tractor trailer interiors to yachts.

The restoration instructions to Artisans were very simple; as long as SAFETY is not an issue, re-use every part you possibly can from either the original car or from Chuck's parts inventory. Chuck had a new concept for the car, which he never really shared, re-naming it "Thunderchief" and he even had white jackets made up with the dark red "Thunderchief" logo on the back - for himself and for my mom, Betty. In the first shot you can see that Chuck was headed towards a different concept for the car, with the roll bar and chrome racing wheels. He had also painted the 1932 Ford Model B truck grill shell white with maroon trim to check out the color scheme he had envisioned. He always remarked that it was so rare to see any white Model A's at the car shows. My Dad never really talked much about his new "vision" of the car, we always were of the mindset that we would be working on it together. After my father passed away, I spent a couple of hours just staring at the car, and feeling bad that I didn't know how to move forward with his "Thunderchief" concept. At one point, my sister came out and gave me a big hug and said - "You know - it's your car now, you can do whatever you want with it. There are no rules or restrictions, just do it your way." It made a big impression on me and although I didn't realize it at the time, the car would eventually find it's way as a modernized version of where she was in 1958. After all, that was the only car I knew. I finally mentioned to Artisans, "You know, we are actually just taking "Bernadine" back to the way she was in 1958," and they said "I have known it for a while and I am glad you realize it too!" Once those words were spoken out loud it became easy as we now had a road map.

I decided to keep the basic color scheme from 1958, but to use a satin finish rather than the original black primer finish, and to stay with the 1950's pinstriping concept. Note the "rolled" door tops which seamlessly anchor the 1947 Kaiser Frazier garnish interior door molding panels by using half of an old muffler, along with the Kaiser Frazier interior door handles. The too sexy external push button door openers are from a 1947 or 1948 Lincoln. They hand fabricated the chrome front and rear bumpers with the front "K" bumper created to resemble a push-car bumper in the sprint car world of the day. The "bobbed"original 1929 rear fenders are also a highlight. The tail lights were from a 1950 Pontiac, while the license plate lights and the front fenders were from motorcycles. The headlights were the original 1936 Pontiac head lights mounted sideways on the grill shell. The grill shell was from a 1932 Ford Model B. The gas tank was from some type of classic truck and the gas cap was fashioned from a too cool radiator cap. The replacement engine block was donated to Chuck from an automotive training center in Detroit. He loved the 1958 Pontiacs and it was the first year they made substantial inroads at NASCAR. He even took the family up to Pontiac, Michigan to tour the Pontiac factory that year. For many years, the Pontiac line for 1958 was looked upon with disdain, and there was a general disrespect for their "different" design. Enthusiasts seemed to gravitate to the clean style of the 1955, '56 and '57 models, as well as the larger 1959 and '60 models. But for those in the know, the '58 models were a true turning point in GM's bold new way of thinking with respect to styling and design. Pontiac Motor Division referred to the redesigned line in their advertising with the slogan, "The Boldest Advance in Fifty Years." When the racy `58 Bonneville was fitted with Tri-Power carburetors, it made for a desirable - and speedy - cruiser. Perhaps this is why a Tri-Power `58 Bonneville was chosen to pace the Indy 500 that year and that the 1958 motors started showing up at NASCAR races. The cylinder heads Chuck used were from a 1955 Pontiac. He fashioned the Offenhauser log style racing manifold himself from a kit as well as using a number of Offenhauser racing components, giving it in excess of 400 horsepower. The six two barrel Stromberg 97 carbs top off the new engine design. Chuck was an old school "rodder" who would fashion parts for the car as he went along, grabbing parts from anything he could find at auctions, yard sales, junk yards - or the parts that he kept from cars which landed as totaled in their body shop. Hence the nickname and license plate "Mutt Rod". This original car features suspension parts from both the '36 and '39 Pontiacs they raced. The bottom photo shows some of the other custom creations in various states of progress at the Artisan shop.

THE RESTORATION BEGINS:

Artisans already had their hands full on the car, from doing a complete inventory of all the parts, getting an appraisal for the estate, and organizing the future workflow on the car. We finally got the car insured, registered and licensed out of New York and we love the "MUTT ROD" plates we managed to score. They cut out the roll bar, pulled the engine, took off the wheels and put the car up on blocks, so they could thoroughly examine and inspect the frame, steering, clutch, suspension and brake components. It was discovered that the frame had been weakened considerably, as some chunks of the "C" channel along the edges on the top and on both sides of the frame had been removed to accommodate the oversize Pontiac V8. I observed that the frame had too much "give" and was easily moved by simply leaning or pushing on one side of it. I am thankful that Chuck had not completed it as is, because the vehicle may not have been safe with that oversize engine and weakened frame. The torque from the engine could actually cause the frame to twist or buckle slightly which could have wreaked havoc on the handling of the car. We had to make some tough decisions this time around and ultimately decided to purchase an entire new1929 Model A frame. Safety is paramount and although we want to utilize as much of the original car and parts as possible, we have to insure that the car will be safe to drive. The engine fired fine, although it was not running long enough to insure the seals are still ok. We are going to keep the Pontiac engine and drive train intact and replace some of the brake components and a good portion of the suspension. We have decided to go with no air conditioning, no power steering, and no radio. We also decided upon an original steel dash instead of a custom wooden one. While I was in Indiana, we discovered Chuck's technical notes on the carburetor settings. Not just any mechanic knows how to sync up and maintain those carburetors. Chuck's notes should prove to be very helpful. The meeting with Marcus on the interior was such a treat. Seeing his shop and his work, what an incredibly dedicated and talented ARTIST he is! We sketched out some general plans but realized that ultimately, you need to let the car come to you as it is built, and that the vision of the interior will reveal itself as the car progresses.

It has been a couple of grueling months facing the tedious task of gathering parts, measuring the fit and removing all of the usable suspension parts from the old 1936 Pontiac frame. It's going to be a real challenge to get everything fitted and attached to the new custom frame and get back to a rolling chassis. Artisan Rods sent some photos and in this first photo you can see that the body is sitting up on top of the frame, creating a "highboy" style rod. The highboys originated in California and are generally considered to be a West Coast build. We don't particularly care for the highboy look, it has always looked "boxy" to us. We prefer the sexy, channeled low-boy look of the East Coast Rods. Even though it will cost more, and create hours of additional labor charges, I have asked Artisans go back to the same 4" channel on the original "Bernadine". This means that the body will slip down over the frame about 4". This also means that the oversized motor will need to be channeled 4" also in order to facilitate the hood we have envisioned for the car:

You can see the work involved on the cowl and body braces in order to get the body to slip down over the frame 4":

Here is the Pontiac V8 basically in place. However, when the body drops 4" the engine has to drop 4" as well, creating a problem for the current exhaust manifolds whose size make the motor too wide for the frame. We will have to fabricate custom exhaust manifolds for the car.

Here is another shot of the motor from the other side:

A rolling chassis! Just returned from Indiana, and spent some quality time at the Artisan Rod shop. Also spent time with Marcus Marquart finalizing the interior color choices and getting samples to Artisans for paint matching purposes. Here is a picture of the current status of the car. The '32 Ford grill shell is close to proper positioning, but not yet bolted in place, as it is still being precisely fitted. The new steel firewall the shop fabricated is welded into place. The gas tank is mounted inside the body between what will be the seat and the trunk. We are also grateful to see that it is possible with the lower engine and the perfectly aligned grill shell that the half hood we had envisioned will be possible. The half hood would stretch from the cowl to the grill shell and will clear the carburetors only by a very slim margin. This wasn't possible with the original frame for a number of reasons. Also, the rear fenders have been temporarily removed to facilitate easier removal of the body from the frame. Please note that Artisans will need to add steel to extend the windshield posts upward holding the windshield and also all the way across. The steelwork is first rate. We originally thought that we would end up with a transmission hump in the floor, due to channeling the body 4", but happily, the floor sits nice and flat. We also realized with the channeling that we can't use a conventional Model A seat frame. It would simply sit too high now, you would be looking over the windshield. Artisans advised that due to the safety of the gas tank, we should remove the lightweight tin Chuck had fabricated around the body's interior and replace it with heavy gauge steel. Here is a shot from over the passenger door:

Another shot of the steel floor from the driver's door. You can see the tin Chuck had fabricated which needs to be removed. It starts to the left of the speaker hole at the edge of the door panels and wraps all the way around to other side and behind the seat. This will be replaced with heavy duty steel to create a more substantial barrier between the seat and the gas tank.

Another shot of the tin that needs to be removed along with a glimpse of the gas tank:

Here is a picture of the rear suspension. Note how heavy duty the Model A Frame is:

Here is a view of the car from the rear. I must say, I miss seeing those bobbed fenders, they make the car, especially the view from behind. Artisans and his staff also did a nice job finishing up the steel lining inside the trunk area. The next step is to carve out the battery holder.

We also discussed the utilization of the convertible top frame that Chuck fabricated. We have never been wild about the look of the original 1929 Model A canvas top. However, with Chuck's frame combined with the design sense and expertise of Artisans and Marcus, a convertible top could have decent visual appeal and still present a practical solution for getting the car from place to place in inclement weather. Artisans took a look and said the convertible frame Chuck fabricated was pretty much ready to go with some narrowing and cosmetic touches. We have no idea where Chuck got this unique frame but our guess is that it was from an old horse drawn buggy, or else from a boat. Here is an early pic that Chuck took with the convertible top frame in place as he had envisioned it:

Lots of news along with some new photos. The battery box in the trunk is now complete, the convertible top frame is now mounted and part of the car, and the grill shell is mounted, along with the support rods which go from the grill shell to the firewall. The exhaust manifold is now complete, and the dash is mounted in the car. The 1947 Pontiac transmission has been pulled and sent out to be double checked and serviced. The body has been fabricated with new upper windshield posts and upper body supports across the top of the windshield in order to secure the original windshield frame. We found the tri-spinner "planet" '56 Olds hubcaps at the mother of all swap meets in Hershey, Pennsylvania last weekend, along with another Lincoln push button we may be able to utilize for the trunk. Here are the pictures from today courtesy of Artisan Rods & Classics:

wears prada prada boots white prada sungl outlets adidas cardinal materials outlet usa online prada brown bags prada pr 10yv prada vest women's prada bag charm store gucci women's suit outlet prada sunglasses swirl gucci fashion house prada refill perfume specialty printing services prada watch ladies prada womens jeans prada long wallet franchise fried chicken fendi prada lyrics light up light up get chatgpt florence prada prada frank ocean prada padded jacket prada sunglasses bloomingdale's makeup calculator prada crystal skirt prada green sneakers tacones prada instagram usa followers growing colors by bruce mcmillan gucci b large pin boards fajas de prada prada thongs underwear prada riding boots italian restaurants in rosemont mosaic locations in florida prada notebook prada t shirts prada triangle loafer instagram followers money prada carbon black fast followers instagram lunch rosemont new prada cologne prada arca camisas prada hombre fashion outlets online prada adidas superstar ferragamo outlet store online cardinal building group instagram api followers the gucci store mosaic tampa fl prada thong bikini printing concepts inc high end outlet instagram followers reports chatgpt что это private instagram followers prada eyewear women biz markie jeff goldblum prada double match new instagram followers prada green sneakers prada bag black chatgpt ethics biz markie jeff goldblum prada cleo dupe prada frank ocean element construction discord chatgpt prada shoulder purse paid instagram followers meundies boxer williams chicken fort worth tx element construction instagram followers disappearing new instagram followers prada gold sunglasses duration sierra gray shingles premier gymnastics lutz gratis followers instagram women's prada shades prada blue bags camisa prada hombre купить гуччи real captains hat chatgpt wordpress plugin fiverr instagram followers nautical captain hat

Greetings from Indiana. Had quite a time here with Artisans and Marcus Marquart both on the scene to help make some final decisions about fitting and latching the convertible top, fitting the pedals and the steering wheel and column and finalizing the plans for the custom seat. Won a very cool 18" banjo steering wheel on an ebay auction from a 1936 Oldsmobile. Here it is:

The next photo below shows the seat frame mock-up used to determine how we are going to custom make the seat frame. I sat in the car while Marcus and Artisans took their measurements. Due to the channeling of the body, the seat frame will have to rise up a short 2" from the floor in the front and be directly on the floor in the back. There is no room for seat springs so the seat will be constructed of wood and foam cushions. The second shot shows a nice view of the 1947 Kaiser Frazier garnish moldings on the upper portion of the inside of the doors and the Frazier inside door handles. In the next frame you can get a clear view of the exhaust pipes which had to be individually tooled and fitted. Next you can see the steel dash ready to paint before installing the gauges as well as the retrofit which had to be made on the 1947 Pontiac transmission. In 1947 all Pontiac transmissions had column shifters not floor shifters. The guys at Artisan retrofitted the transmission to allow it to be used with a handshaker type floor shifter. However, we are now weighing the pros and cons of moving to an automatic transmission.

Just got back from Indiana for a few days and spent some time with Artisans at Artisans. We finalized the decision to move forward with a three speed automatic transmission. Anyone looking for a 1947 Pontiac manual transmission with a floor shifter kit installed and in great shape? They have also finished the steering column mounts and removed the manual transmission. They estimate that there are an additional 240 hours of labor left on the the restoration of the car, including drive train, disassembly, painting, re-assembly and completing all the systems work such as brakes, and electrical. Should be some new pictures soon. I would like to thank my childhood friend, photographer extraordinaire, Johnny "Chicago" Hornberger for photoshopping the picture from 1958 which had annoying creases across it. It appears at the very top of this page and he did an incredible job of restoring the photo.

Had an extended conversation with Artisans today. They have finished all of the upper body welding; including welding and grinding the final cosmetic phase of the firewall. They have received the heater, the whitewall tires, the transmission adaptor and the transmission. They should have the drive train finished next week. After the transmission installation it is a matter of shortening and connecting the drive shaft.

Just got some new photos from Artisans! The first photo shows the heater installation, the gauges temporarily mounted, along with the 1977 Firebird steering column installation. The automatic transmission has been fitted and mounted, along with the transmission adaptor. The second picture shows the steel base of the seat frame which has also been fabricated. The third and fourth pictures show the new steel half-hood that Artisans have rolled and fabricated for the car. They are really making progress now:

Got a picture from Artisans today. A bit difficult to see by looking, but the bolt patterns on the front vs. rear wheels were slightly different, which created a need to get two matching front and two different matching rear wheels. We picked up the wheels at a local junkyard, and Artisans had the wheels sandblasted. Then Artisans painted them dark red, which will match the motor and interior highlights, and got the vintage wide whitewall tires mounted. Artisans likes the badass look of no fenders and no hubcaps as he tends to lean towards the rat rod world. If this was his car he would probably choose not to paint it at all, but to simply leave it exactly as is.

They also put brand new modern door latches on both doors. This turned out to be quite a project as they had to cut the door panel in order to get to the bolts on the back of the door handle on the driver's side. Turns out my Dad and my Uncle used an old muffler, cut it in half and positioned it on top of each of the door frames to give that smooth no window look - and to connect the Frazier door panels to the door. They then filled it with lead and sanded it smooth. Artisans was amazed at the pile of lead which accumulated as they were taking the door apart. This photo shows the bands of the muffler and I think you can see what a project this was::

Just completed a very productive trip to Indiana. New pictures below courtesy of our lifelong friend, Johnny "Chicago" Hornberger, who took a ride out to Artisans with me. The only remaining issues are putting in the truck lock/latch and then pulling the body. The body needs some comprehensive welding work on the underside around the new floor and trunk areas. Once the body is off, the fuel lines and brake lines can be installed on the chassis. Then, it's time to get the motor, the chassis and the body prepped for painting. Note in the last photo you can see the cool effect of the tri-spinner hubcaps along with the fenders. Artisans put the headlamp fixtures and front bumper on temporarily to get an idea of the "look" of the front of the car. We are also discussing the idea of using baffles in the lake pipes to quiet the car down, rather than feeding the pipes under the car and into Chuck's muffler system. Don't know what the neighbors might think but we love the idea of the baffles and we are going to try that first.

Got some pics from Artisans at Artisans this morning and the car has now been disassembled to begin the paint prep process. Here is a shot of the motor painted deep carmine red, to match exactly all of the other red highlights on the car. The motor is ready to pop back in, and the chassis is primed and ready for paint. The body is still a work in progress, and is being prepared for primer.

CHUCK'S MOTOR

A WORD ABOUT THE 1958 PONTIAC 370 CI POWER PLANT IN "BERNADINE"

from Hemmings Motor News, article here: Hemmings Motor News

As Pontiac enthusiasts have long known, the heart of every V-8-powered Pontiac is its engine. These big-bore power plants are engineering masterpieces, and are considered by many professional engine builders to be the very best carbureted V-8 engines that General Motors ever produced. The reasons are many.

Introduced for the 1955 model year sporting 287 cubic inches, the cylinder block was enlarged to 316 for 1956, 347 for 1957 then to 370 cubes for the 1958 models before Pontiac engineers settled on the 389-cubic-inch displacement for 1959. The 389 lasted through the 1966 model run before being enlarged to 400, then 455 cubic inches.

Based on a 90-degree design, the 370-cu.in. overhead-valve V-8 had a bore and stroke of 4.06 x 3.56 inches. The stout blocks were overbuilt with unusually thick webbing, strong bulkheads surrounding the main bearing and thick walls surrounding each cylinder bore. Ultra-tough forged steel crankshafts with wide 2.625-inch diameter main journals and super-strong forged steel connecting rods with wide 2.25-inch diameter big-end journals and full floating wrist pins were the reason the 370's bottom end is so indestructible; in fact, so well-designed were these long 6.625-inch rods that they were used throughout the Pontiac V-8's entire production span, and that lasted until 1978!

And if that wasn't enough, a windage tray was standard. The windage tray, which was fastened atop the crankshaft's main caps, scrapes the oil off the crankshaft as it spins, reducing the oil's parasitic drag and freeing up a few horsepower.

Up top, the cast-iron cylinder heads featured dual springs per valve to insure positive sealing while eliminating valve float at high rpm. More importantly, specially designed rocker-arm studs accurately located the rocker-arm nuts for correct preload of the hydraulic lifters-this rocker-arm design eliminates the need for regular adjustments.

Between the cylinder heads sits a heavy cast-iron dual-plane intake manifold to which a Carter AFB four-barrel carburetor is fitted. Late in the model year, some 500 cars were fitted with a Rochester 4GC four-barrel carburetor. All Tri-Power units used Rochester two-barrel carburetors with vacuum activated linkage.

To ensure that the cylinder heads were secured to the block as firmly as possible, ten beefy 1/2-inch bolts were used. Each bolt was anchored into special bosses that were cast into the outer walls of the block, as opposed to the more usual location of the water jackets or cylinder walls. This sound engineering principle helped minimize distortion of the cylinder bores when the bolts were torqued down, in addition to eliminating any potential water leaks.

Another outstanding production technique that was a characteristic of Pontiac's advanced design and engineering was the machining of the combustion chambers. This process creates identically sized chamber volumes for all eight combustion chambers, thus ensuring the same power output for each cylinder. Raw cast chambers that are not machined, which is the typical cylinder head finish used by all the other auto manufacturers, do not have equally precise chamber volumes, thus causing the power output of each cylinder to vary slightly which, in turn, affects the engine's smoothness.

REVERSE COOLING IN THE 1958 PONTIAC POWER PLANT IN "BERNADINE"

1958 Pontiac motors had a cooling system which uses reverse flow circulation for maximum cooling efficiency. In reverse flow, cooled water from the radiator passes first to the cylinder heads, which are the hottest parts of the engine, and then to the cylinder block which is the coolest portion of the engine.

Water enters each cylinder head from the pump through a water distributing tube that is inserted into each cylinder head. Openings in the water distributing tube direct coolant in jet fashion onto valve seats and around each exhaust passage. This feature is referred to as “gusher valve cooling”.

The combination of reverse flow circulation and gusher valve cooling results in relatively low operating temperature of valves and valve seats. Valve life is greatly increased, therefore, and valve seat inserts are not required.

With reverse flow circulation no cooled water is thrown directly on cylinder walls to cause cylinder distortion. Sludging of engine oil is minimized since highest temperature coolants are retained in the cylinder block, particularly during warm-up, and condensation on cylinder bores is thereby reduced. Water circulation during warm-up (thermostat closed) is from the pump to the water distributing tubes to the cylinder heads.

Water circulation after normal operating temperatures are reached (thermostat open) takes two courses. Part of the water will always recirculate through the block as outlined above. A large portion of the water, however, will pass from the pump to the water distributing tubes, to the heads, and thence directly into the top of the radiator through the water outlet page in the front of the intake manifold. The 1959 Shop Manual talks about why reverse flow cooling was used and extols the benefits of reverse flow and gusher valve cooling. Why did Pontiac abandon the documented superior cooling system and switch to conventional flow in the 1960 model year without any explanation? No one seems to know for sure.

CHUCK'S MOTOR WITH RICK'S PRACTICAL CHANGES

The only changes Rick made to Chuck's Pontiac 370 were born out of practicality. We tried hard to use the Offenhauser style manifold that Chuck built from a kit - and the Stromberg two barrel Six-Pack - but after a ridiculous amount of time spent, we just couldn't get it to idle smoothly. The compression ratio is close to 13:1 and it's a wonder she will idle at all. Luckily, Chuck had both a tri-power manifold and a four-barrel manifold waiting in the wings. Since this car is a driver, we didn't want to be spending an inordinate amount of time by the side of the road dealing with the humidity sensitive Strombergs, plus we loved the automatic choke on the modern Edelbrock four barrel. We capped it off with a Cadillac style air cleaner which we had pinstriped by Jim Studinski. We also were forced to replace Chuck's original valve covers, as they were beginning to pit through the chrome on the top of the valve covers and oil was leaking out directly onto the covers. After all, they were on the motor since 1960! Another change since this photo was taken, is that the Zoomie exhaust pipes have been unwrapped and ceramic coated black.

Just got back from another whirlwind trip to Indiana to check in on the Mutt Rod and attend my nieces wedding reception (Congratulations Megan, Shane is a great guy!). We had the car pinstriped and photographed complete with extensive interviews with both the major newspapers, the Journal Gazette and the News Sentinel in Fort Wayne, Indiana. Thanks to Amanda Junk from the Fort Wayne News Sentinel for spending so much time with us last wednesday, and special thanks to Rosa Salter of the Journal Gazette for turning us on to the 1957 Pat Boone hit "Bernadine" and for spending so much time with us last thursday. What a perfect theme song the Pat Boone hit is for this beast of a car! And as I find out later from Ronnie Reed - who worked for Kennell Brothers back in the day - the car was actually named after the song. The car is basically finished on the mechanical side except for some issues with the Strombergs and we got it over to Marcus Marquart of Marquart Custom Creations, in Waynedale, Indiana to do the interior and convertible top yesterday. We need to do some other de-bugging work when the car gets back to the Artisans Rod shop. We discovered that the motor has a compression ratio of approximately 13:1, basically a NASCAR racing setup for that era, which is ridiculous for a street car.

Just returned from Indiana and the Muddy River Run, where we picked up the Don Hall's Guesthouse SPECIAL CHOICE AWARD among the field of 436 cars. It was gratifying to meet all the friends and admirers of Bud and Chuck and we are especially excited about the possibility of getting more stuff for the archives from several people we met at the show. More pictures from the 1958 Hot Rod show and possibly some videos of the 1936 Pontiac race car performing at the speedway may be coming. Marcus Marquart took some photos of the interior work and the fabrication of the convertible top in progress and we have posted those pictures here:

(LEFT): BERNADINE WITH UNCLE BUD KENNELL IN THE DRIVER'S SEAT IN 1958

(RIGHT): BERNADINE WITH RICK KENNELL IN THE DRIVER'S SEAT - 50 YEARS LATER - ALMOST TO THE DAY!

VIVA LA BERNADINE!

Here is "Bernadine" as photographed by the legendary girlie and classic car photographer Viva Van Story for Car Kulture Deluxe Magazine. She might be a Ford but note the "POWERED BY GENERAL MOTORS" on the1936 Oldsmobile banjo steering wheel.

A QUESTION?

OK, so it is 2014 and the car has been prominently featured in a national hot rod magazine and won "Best of Show" awards in her category in two states. The original concept in 2007 was to honor my father Chuck and my Uncle Bud who were the original builders of the car, by taking her back to the way she was in 1958. It might be getting to be the time to give her a facelift.

I love the red motor and wheels and the black and red interior so I would ultimately like to leave the cockpit alone. With that in mind, the color choices that would feel good and work well with the black and red interior are actually pretty limited. If I keep her satin black, I am thinking of taking the "Bernadine" logo off. I am also thinking of changing her to another color. Due to the miracle of Photoshop, you can see these colors below and I would appreciate it if you would drop me a line and let me know which color you think would stand out on her the best. Please note that the photoshop silhouette requires that the finish appear satin - although in reality, solid glosses are everywhere and appear to be making a huge comeback. So the final finish would more than likely be gloss.

Black, removing logo:

Blue:

Silver:

Bright Gold:

Pearl White:

Carmine Red to match the wheels and motor - although I would probably paint the grille black:

Bronze Gold:

© indieFINANCIALnetwork� All RIghts Reserved